Our Services

-

Level III Consulting

Manage the qualification and certification of NDT personnel to ASNT-TC-1A & NAS 410, audit NDT systems and handle compliance of all NDT processes and systems. The NDT Level III shall be recognized internally and externally as a technical expert in their field. AQI L-III is competent to act as a technical liaison representing AQI as a prime technical contact.

-

Ultrasonic Testing

Ultrasonic Testing (UT) is a non-destructive testing technique based on the propagation of ultrasonic waves in a object or material. In most common UT applications, very short ultrasonic pulse waves, are transmitted into materials to detect internal flaws or to characterize materials. Ultrasonic testing is extensively used to detect flaws in welds, composites, and many other materials.

-

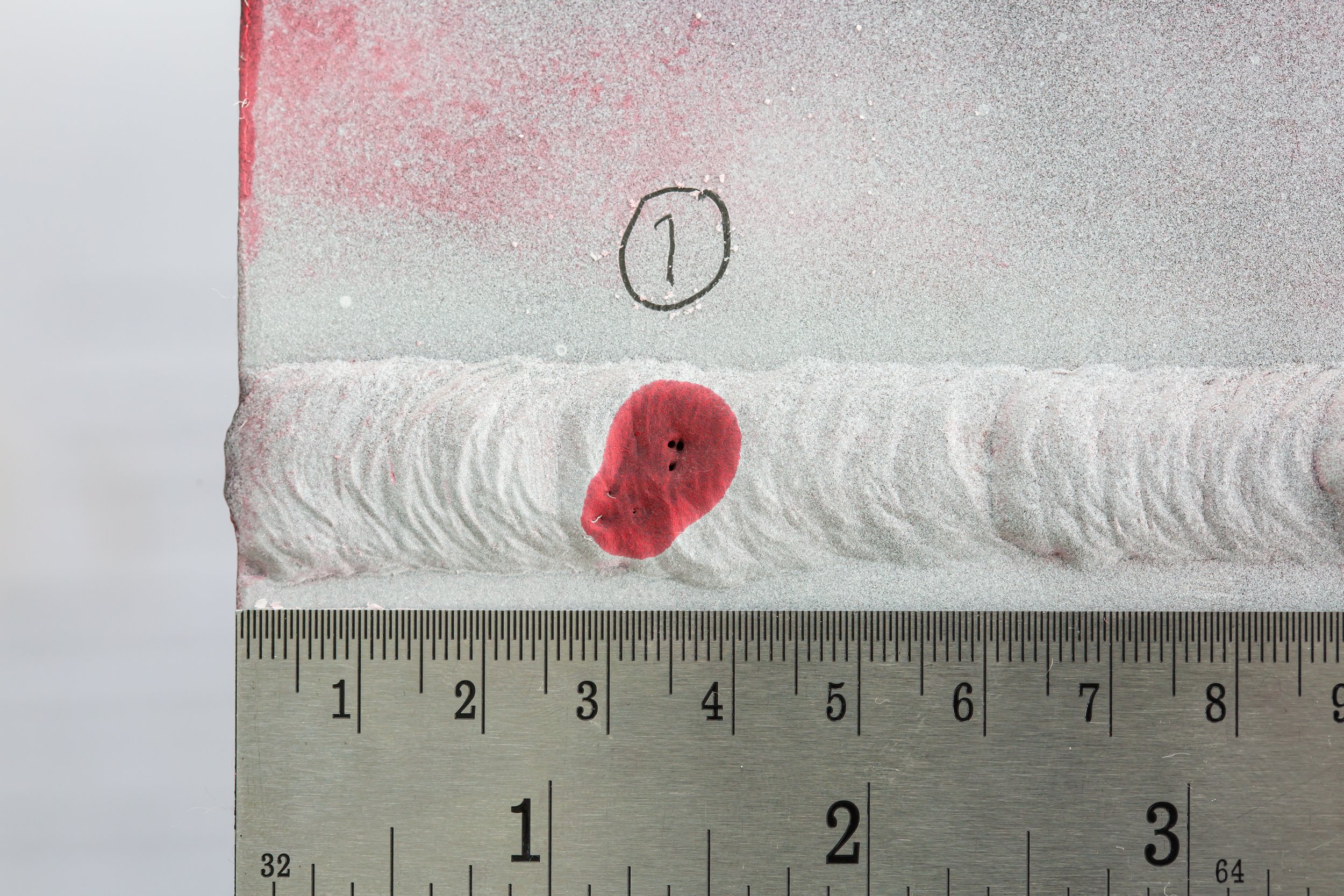

Liquid Penetrant Testing

Liquid Penetrant Testing (PT) is a non-destructive testing method that uses capillary forces to locate surface-breaking flaws such as cracks, laps and porosity. The flaw must reach the surface in order to be tested, but liquid penetrant testing offers an inexpensive solution for testing large areas quickly.

-

Magnetic Particle Testing

Magnetic Particle Testing (MT) is a non-destructive testing technique where a magnetic field is used for detecting surface, and shallow subsurface, discontinuities in ferromagnetic materials.

-

Visual & Dimensional Testing

Visual & Dimensional Testing (VT) is a non-destructive testing technique. It is intended to find and mark for repair obvious visual nonconformances such as cracks, surface porosity, dimensional discrepancies, excess concavity or convexity, unfilled areas, undercut, misalignment, craters, unacceptable arc striking spots and any other objectionable visual features.

-

Radiography Inspection

Available for Film Interpretation.